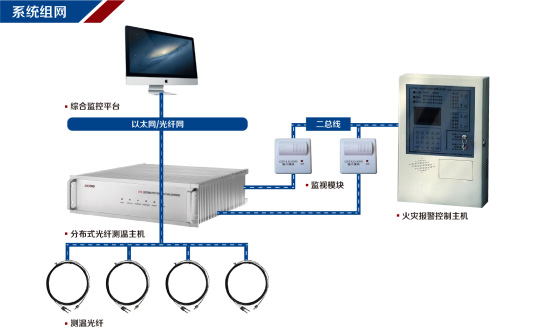

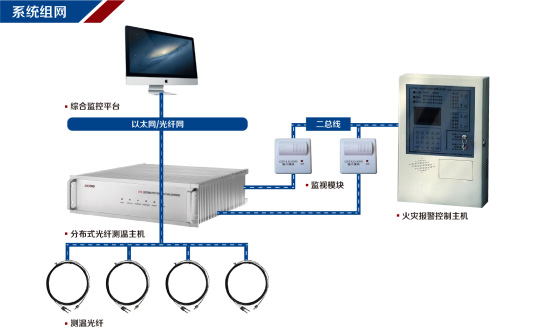

System Description: distributed optical fiber thermometer (dt-412c) is a kind of optical time domain temperature monitoring system, which is a mature distributed optical fiber temperature measurement system at home and abroad. The system is composed of temperature measuring host (dt-412c), temperature sensing optical fiber and DTS background analysis software. It is based on the principle of Raman scattering in light, integrates the temperature sensitive characteristics of OTDR and Raman scattering light, detects the temperature changes of different positions along the optical fiber, and realizes real distributed measurement through intelligent analysis of DTS background software data, which can continuously measure the temperature of any point along the optical fiber. The measurement distance ranges from several kilometers to tens of kilometers, and the spatial positioning accuracy can reach 1m level. It can carry out continuous real-time online monitoring and remote transmission of real-time data, and can timely warn the fire hazards and accurately locate the fire location. It has the advantages of long measuring distance, no blind area, real-time monitoring and accurate positioning. It is widely used in traffic tunnels, tunnels, subway, electric power, petrochemical, water conservancy and other fields.

System features:

Ø The embedded system is used to complete the design of temperature measurement host;

Ø The main temperature measuring machine adopts the design of no fan refrigeration, with low failure rate and low noise;

Ø distributed real-time measurement, covering 100% of the detection area, no measurement blind area, accurate positioning of fire location;

Ø full name visual display, real-time display of fire development trend and spread direction;

Ø 365 * 24-hour on-line monitoring throughout the year, fundamentally eliminating accidents caused by personnel negligence;

The measurement distance is long and the measurement information is rich;

The measurement accuracy is high and the corresponding speed is fast;

It has high reliability and low false alarm rate;

The alarm mode is flexible, which can realize the multi-level alarm mode of differential and constant temperature to ensure the reliable alarm at the initial stage of fire;

Ø up to 16 different alarm control areas can be set according to the environmental changes. The alarm control area is programmable and can be designed according to the user's requirements. Different alarm values can be set in each individual alarm area;

The temperature measurement system adopts the embedded system design which meets the industrial reliability requirements, and has the functions of network access and remote transmission;

Ø has a network interface, which can be connected with the management network to realize information sharing and further data processing functions.

Industry applications:

Petroleum Industry: oil and gas pipeline monitoring, gas storage tank, oil storage tank monitoring, permanent downhole monitoring;

Petrochemical Industry: liquid storage tank monitoring, transmission pipeline monitoring;

Power industry: cable and transmission line monitoring, cable trench, cable tunnel, cable bridge monitoring;

Granary industry: granary monitoring;

Security industry: fire monitoring of tunnels and special fire buildings;

Transportation industry: cable and transmission line monitoring;

Other industries: distributed optical fiber temperature measurement system can also be used in ammunition depot, dangerous goods warehouse, dam, transmission belt, coal conveying trestle, coal storage yard and other occasions that need space continuous temperature measurement. It is an ideal upgrade substitute for traditional temperature measurement methods (temperature sensing cable, temperature measuring cable).

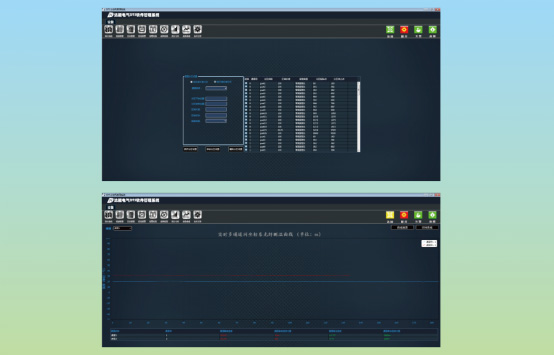

Client software:The user software of distributed temperature measurement system is designed and developed independently. It provides users with humanized and functional Chinese interactive interface, real-time display of temperature distribution curve and alarm status of the area to be tested. It can set multi-level alarm threshold according to the actual working conditions, and provide historical data query and statistical analysis functions. Using advanced Ethernet system architecture based on C / s, the system can be easily and seamlessly connected with the customer LAN. Any computer installed software in the network can quickly access the network, and can access and retrieve temperature data and alarm information.

Functional features:

Ethernet system architecture based on C / S

User friendly Chinese interface

It is easy to use and operate

Visual view, easy to locate

Set multi-level alarm threshold by zone

Historical data query and statistical analysis

Customized development

光纤测温主机

The distributed optical fiber temperature measurement host adopts a number of domestic and foreign advanced photoelectric measurement technology, optical fiber technology, high-performance photoelectric devices and other high-tech as one design. It has the characteristics of long measurement distance (up to 10km), fast response speed (up to 2S / per channel), high temperature measurement accuracy (0.5 ℃ full range), and the key technical indicators are leading in the industry.

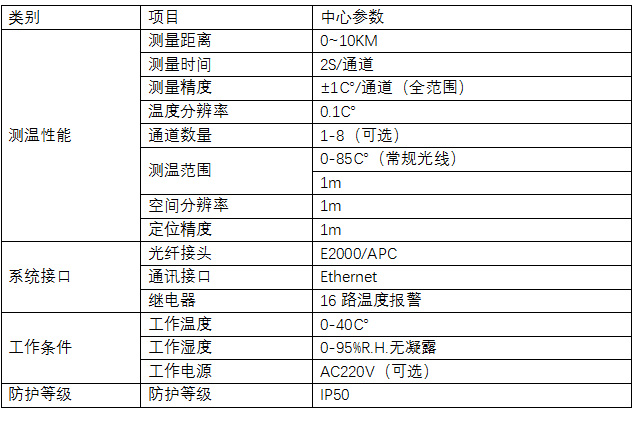

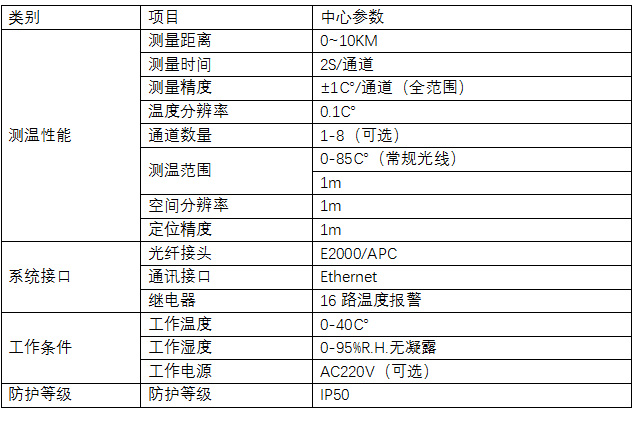

Technical parameters:

Temperature sensing optical cable:

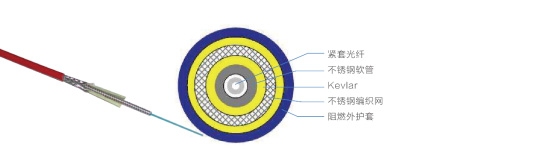

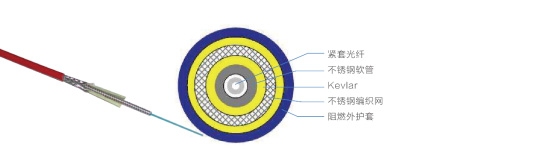

Dts2501 sensing optical cable adopts specially designed fast thermal conductivity optical cable, the fiber core adopts imported gi62.5/125 multimode optical fiber, the optical fiber protective layer adopts high-strength polymer and stainless steel spiral tube armored sheath, and the outer sheath is high-performance low smoke halogen-free flame retardant material, with high tensile strength, bending resistance, good pressure resistance, waterproof, corrosion resistance, high reliability and long service life. The specially designed optical cable structure can not only quickly transfer external heat, but also effectively protect the optical fiber inside the optical cable, and prevent rodents from biting. It is especially suitable for industrial fire monitoring applications and engineering construction needs.

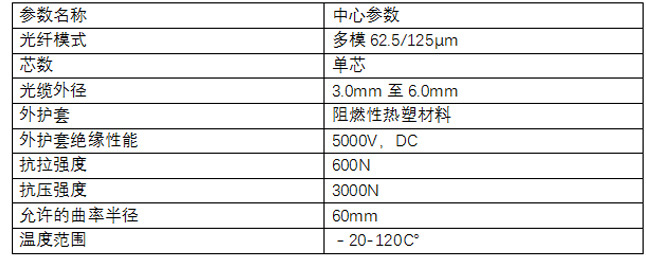

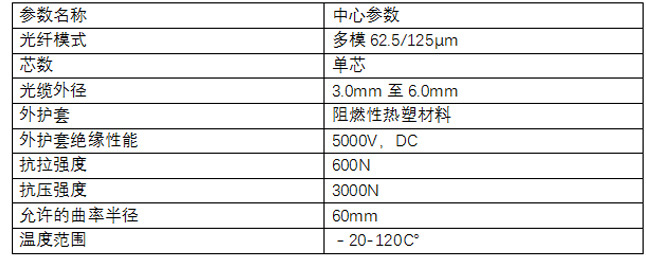

Technical parameters: