About us

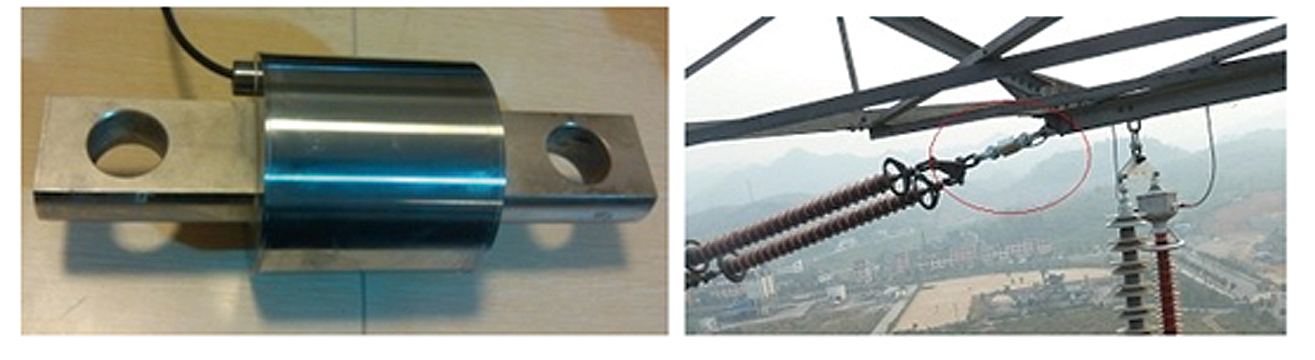

LiaoningDanengElectricCo.,Ltd.(StockCode:832107)isaleadinghigh-techenterpriseintegratingR&D,design,production,salesandconstructionofelectricpowerInternetofthings.

News Center

ThecompanyhascompletequalitymanagementsystemcertificationandLiaoningProvincesafetytechnologypreventionfacilitiesdesignandconstructionqualification,constructionintelligentengineeringprofessionalcontractingqualification,fire-fightingfacilitiesengineeringprofessionalcontractingqualification,installation(repair)powerfacilitieslicenseandotherqualifications,andcanundertakeallkindsofrelatedprojects.Wecustomizecomprehensivesolutionstomeettheneedsofdifferentusers.

Industry and Application

Thecompany'sbusinesscoverspower,petroleumandpetrochemical,urbansecurity,communications,highwaytunnels,coalmines,intelligentbuildingsandotherfields.

Technical support and services

ThecompanyhascompletequalitymanagementsystemcertificationandLiaoningProvincesafetytechnologypreventionfacilitiesdesignandconstructionqualification,constructionintelligentengineeringprofessionalcontractingqualification,fire-fightingfacilitiesengineeringprofessionalcontractingqualification,installation(repair)powerfacilitieslicenseandotherqualifications,andcanundertakeallkindsofrelatedprojects.Wecustomizecomprehensivesolutionstomeettheneedsofdifferentusers.

Research Center

Thecompanyfocusesonprovidingintelligentsubstationintegratedsystemsolutions,publicfacilities(utilitytunnel)intelligentsecurityearlywarningsystemsolutions,powerdatacloudplatformsolutionsandrelatedproducts

Investor relations

ThecompanyprovidesaseriesofcompleteandadvancedpowerandpublicfacilitiescomprehensivesolutionsforvariousapplicationscenariosofStateGrid,ChinaSouthernPowerGrid,ShenyangMetro,ShenyangTaoxianAirportandotherenterprises

Contact us

Thecompanyhasbeenadheringtotheconceptof"R&Dinnovation,excellentquality,professionalservice",adheretotheresponsibilityofleadingthemarket,andconstantlyestablishthecoreadvantagesofthecompany'sproducts